If you are planning to install a metal roof, one crucial aspect to consider is the screw pattern and placement. The way screws are positioned can affect the overall strength and durability of the roof.

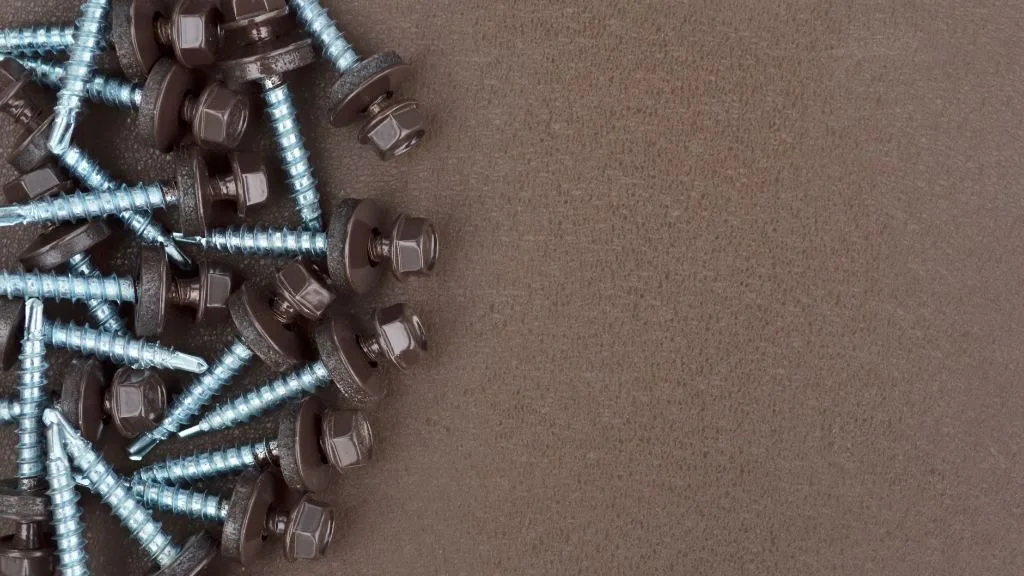

Two common types of metal roofing screws are standing seam and corrugated metal screws. In this article, we will discuss the proper screw pattern and placement for both types of screws to help you achieve a long-lasting and reliable metal roof.

Standing Seam vs Corrugated Metal Roofing

When it comes to choosing between standing seam and corrugated metal roofing, there are several factors to consider. Both options have their own unique features and benefits.

In this section, we will explore the differences between the two types of metal roofing.

Standing Seam Panels

Standing seam metal roofing is a popular choice for both residential and commercial properties. The panels are made of thicker metal, typically 22-24 gauge, making them more durable and able to withstand severe weather conditions such as high winds and hailstorms.

The panels are also installed with concealed fasteners, giving the roof a sleek and modern appearance.

One of the main advantages of standing seam panels is their ability to be installed on roofs with steep slopes. The panels can also be customized to fit the specific needs of the property, including different colors and finishes.

Corrugated Panels

Corrugated metal roofing panels, on the other hand, are thinner and less durable than standing seam panels. They are typically made of 29-26 gauge metal and are not recommended for roofs with low slopes.

However, corrugated panels are a more affordable option and can be easier to install, making them a popular choice for DIY projects.

Corrugated panels are also available in a variety of colors and finishes, allowing property owners to customize the look of their roof. However, the exposed fasteners can detract from the appearance of the roof and may require more maintenance over time.

In summary, standing seam panels are a more durable and long-lasting option for metal roofing, while corrugated panels are a more affordable and easier to install option. When choosing between the two, it is important to consider the specific needs and budget of the property owner.

Screw Pattern and Placement

When it comes to metal roofing installation, screw pattern and placement are critical factors that can affect the durability and overall look of your roof. In this section, we’ll discuss the basics of screw pattern and placement for standing seam and corrugated metal roofs.

Screw Lines and Spacing

The screw lines and spacing determine how many screws are needed to secure the metal roofing panels to the roof deck. Generally, it’s best to place roofing screws one and a half to two feet apart.

Alternatively, make sure that every third corrugation has a screw, including both sides of the panel side lap. The idea is to place the screws close enough to ensure a firm roof installation and far enough not to distort or tear the roofing material.

Screw Location on Panels

The location of screws on metal roofing panels varies depending on the type of panel used. For standing seam roofs, the screws are installed directly into the top of the seam. The seam falls at the center of each 20 or 30-inch panel.

Since the screws are hidden in this style of roof, it’s often considered to be more aesthetically pleasing for residential properties.

On the other hand, screw-down roofs are screwed through the metal, whereas standing seam panels are fastened under each rib. The screw pattern on a metal roof is generally spaced 12-18 inches on the center such that every third corrugation has a screw, including both sides of the panel side-lap.

Fastening Techniques

There are two main types of fastening techniques used for metal roofing installation: exposed fasteners and hidden fasteners. Exposed fasteners are visible on the outside of the roof and are often used in corrugated metal roofs.

Hidden fasteners, on the other hand, are concealed under the panels and are used in standing seam roofs.

When using exposed fasteners, it’s important to pre-drill the screw holes to avoid damaging the metal. For corrugated metal roofs, the screws should be placed in the highs of the corrugation to prevent water from pooling in the valleys.

In conclusion, screw pattern and placement play a crucial role in the installation of metal roofing. By following the guidelines discussed in this section, you can ensure a secure and aesthetically pleasing metal roof that will last for years to come.

Importance of Proper Roof Installation

When it comes to installing a metal roof, proper installation is essential for ensuring its longevity and durability. A properly installed metal roof will be waterproof, energy-efficient, and resistant to expansion and contraction.

In this section, we will discuss the importance of proper roof installation and the various factors that need to be considered during the installation process.

Underlayment and Waterproofing

Before installing a metal roof, it is important to ensure that the underlayment and waterproofing are properly installed. The underlayment serves as a barrier between the roof deck and the metal panels, while the waterproofing ensures that the roof is water-resistant.

Without proper underlayment and waterproofing, your roof will be vulnerable to leaks and water damage.

Expansion and Contraction

Metal roofs are known for their resistance to expansion and contraction, but this can only be achieved if the panels are properly installed. Improper installation can lead to buckling and warping, which can compromise the roof’s durability and energy efficiency.

It is important to follow the manufacturer’s guidelines for panel installation and ensure that the panels are properly fastened.

Trim and Clips

Trim and clips are an important part of the metal roof installation process. They help to secure the panels in place and ensure that the roof is properly aligned.

Without proper trim and clips, your roof may be vulnerable to wind damage and other types of weather-related damage. It is important to use high-quality trim and clips and to ensure that they are properly installed.

Roofing Square and Order

Roofing square and order are important considerations when installing a metal roof. The roofing square refers to the amount of roofing material needed to cover 100 square feet of roof surface.

The order refers to the number of panels needed to cover the entire roof. It is important to calculate the roofing square and order accurately to ensure that you have enough material for the entire roof.

In conclusion, proper roof installation is essential for ensuring the longevity and durability of a metal roof. By considering factors such as underlayment and waterproofing, expansion and contraction, trim and clips, and roofing square and order, you can ensure that your roof is properly installed and maintained.

With proper installation and maintenance, your metal roof can provide many years of reliable service and energy efficiency.

Common Issues with Screw Pattern and Placement

When it comes to metal roofing, screw pattern and placement are crucial factors that can make or break the durability of your roof. While screws are necessary to secure the metal panels to the roof deck, using too few or too many screws can cause serious problems.

In this section, we’ll discuss some common issues that can arise from improper screw pattern and placement.

Leakage

One of the most common issues with screw pattern and placement is leakage. If the screws are not placed correctly, water can seep through the gaps and cause leaks. This can lead to serious damage to your roof and the interior of your home.

To avoid this, it is important to follow the manufacturer’s guidelines for screw placement. This will ensure that the screws are placed in the right locations and at the right intervals to prevent leaks.

Weak Roofing

Another issue that can arise from improper screw pattern and placement is weak roofing. If there are too few screws, the metal panels can become loose and start to lift in high winds.

On the other hand, if there are too many screws, the metal panels can become warped and distorted. This can weaken the overall structure of the roof and make it more susceptible to damage from extreme weather events.

To avoid weak roofing, it is important to strike the right balance between too few and too many screws. This will ensure that the metal panels are securely fastened to the roof deck without causing unnecessary stress on the material.

Additionally, it is important to use high-quality screws that are designed specifically for metal roofing. This will ensure that the screws are strong enough to withstand the elements and provide long-lasting protection for your home.

In summary, screw pattern and placement are critical factors that can affect the durability and longevity of your metal roof. By following the manufacturer’s guidelines and striking the right balance between too few and too many screws, you can ensure that your roof provides reliable protection for years to come.

Conclusion

When it comes to standing seam and corrugated metal roofs, the screw pattern and placement are crucial for the roof’s longevity and durability. By following the proper screw pattern and placement guidelines, you can ensure that your roof will withstand strong winds and storms while requiring minimal maintenance.

For standing seam roofs, the screws should be placed directly into the top of the seam at the center of each 20- or 30-inch panel piece. This screw pattern is one screw placement per panel section across the full width and length of the roof.

This placement ensures that the screws are hidden, making it more aesthetically pleasing for residential properties.

On the other hand, for corrugated metal roofs, the screws should be spaced 12-18 inches on the center such that every third corrugation has a screw, including both sides of the panel side-lap. This placement ensures a secure connection, but the screws are exposed to more water and debris.

If you are installing Western Rib or 7.2 panel, the rib installation should be used for screw placement. This method ensures that the screws are fastened under each rib, making it more secure and durable.

It is also essential to consider the attic’s ventilation when installing a metal roof. Proper ventilation can help prevent moisture buildup and extend the roof’s lifespan.

In conclusion, proper screw pattern and placement are crucial for the longevity and durability of your standing seam or corrugated metal roof.

By following the guidelines and considering other factors such as ventilation, you can ensure that your roof will withstand strong winds and storms while requiring minimal maintenance.